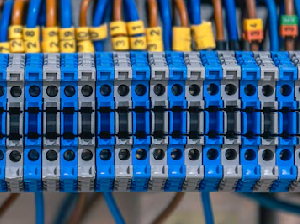

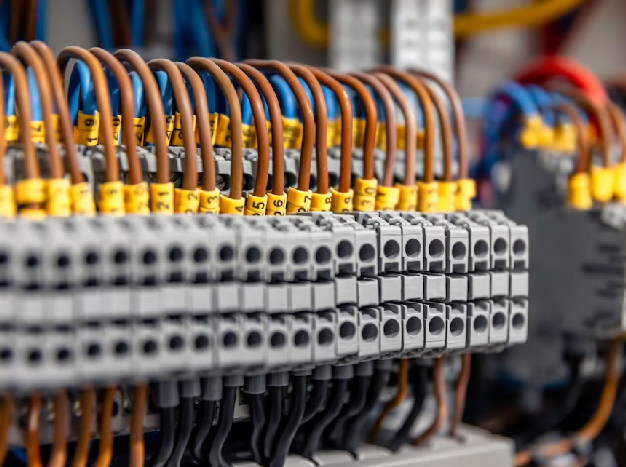

Electrical Installations

We provide expert installation of electrical systems, including wiring, lighting, circuit breakers, and panels, ensuring a safe and functional environment for your property.

Maintenance and Repairs

Our technicians offer prompt maintenance and repair services for all electrical components, addressing issues such as faulty wiring, power outages, and equipment malfunctions to minimize downtime.

Lighting Solutions

We design and install a variety of lighting systems, from ambient lighting to specialized industrial solutions, enhancing both functionality and aesthetics.

Power Distribution

Our team specializes in power distribution systems, ensuring efficient energy flow and management throughout your facility, including transformers and switchgear.

Electrical Testing and Inspections

We conduct thorough testing and inspections to assess the safety and efficiency of existing electrical systems, identifying potential hazards and ensuring compliance with regulations.

Renewable Energy Solutions

We offer installation services for solar panels and other renewable energy systems, helping you reduce energy costs and minimize environmental impact.

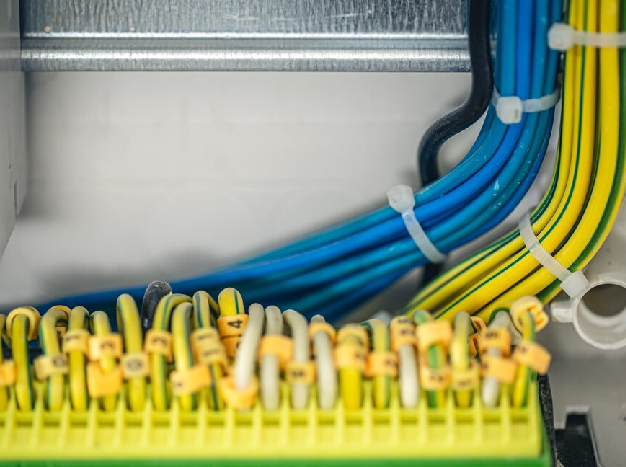

Installation of GI cable trays

The installation of GI (Galvanized Iron) cable trays involves careful planning and execution to provide reliable support for electrical cables. First, a route is determined, and mounting brackets are securely fixed to walls or ceilings at appropriate intervals. Next, the GI cable tray sections are assembled and attached to these supports using bolts and nuts, ensuring everything is level and stable. Cables are then routed through the trays, secured with cable ties to maintain organization and prevent damage. Finally, a thorough inspection is conducted to verify that all connections are tight and that the installation complies with safety and electrical codes. Regular maintenance checks are essential to ensure the integrity and safety of the installation over time.

GI Trunking

GI trunking, or Galvanized Iron trunking, is a robust and durable conduit system used for protecting and organizing electrical cables in various industrial and commercial applications. Made from galvanized steel, GI trunking provides excellent resistance to corrosion, making it ideal for environments exposed to moisture or harsh conditions. Its design typically features a rectangular or square shape, allowing for easy installation along walls or ceilings while accommodating a wide range of cable sizes. The trunking system not only safeguards cables from physical damage but also facilitates efficient cable management, ensuring a tidy and organized appearance. Additionally, GI trunking can be fitted with removable covers for easy access to the cables, simplifying maintenance and modifications as needed.

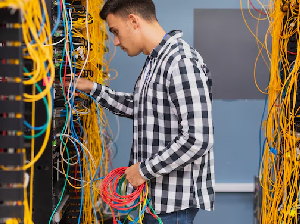

Cable Pulling

Cable pulling is the process of installing electrical cables through conduits, ducts, or cable trays, ensuring that they are properly routed to their designated locations. This procedure typically involves using specialized tools such as cable pullers or winches to exert controlled tension, minimizing the risk of damage to the cables during installation. Proper planning is essential, including assessing cable length, weight, and the layout of the route to avoid sharp bends or excessive friction that could compromise cable integrity. Effective techniques, such as using lubricant or guiding systems, can help facilitate smoother pulling, particularly in long runs or complex pathways. Ensuring safe practices during cable pulling is crucial to maintain both the integrity of the cables and the safety of the installation team.

GI and PVC conduiting

GI (Galvanized Iron) and PVC (Polyvinyl Chloride) conduits are two popular types of piping used for electrical wiring protection and management. GI conduits are made from galvanized steel, offering high durability and resistance to corrosion, making them suitable for harsh environments and outdoor applications. They are often used in industrial settings where mechanical protection is essential. In contrast, PVC conduits are lightweight, non-corrosive, and easy to install, making them ideal for residential and commercial applications. PVC is also resistant to moisture and various chemicals, which enhances its longevity. Both types of conduits provide a secure pathway for electrical cables, ensuring safety and organization, while the choice between them typically depends on the specific environmental conditions and installation requirements.